In vitro diagnostics (IVD) are an essential part of the medical industry, providing accurate and reliable results for a wide range of tests. However, with the growing complexity and efficiency of IVD equipment, there is increasing pressure on innovators and contract manufacturers to produce instruments that are not only reliable but also easy to use and safe. One way to achieve this is through the use of fluid connectors, which can enhance the reliability and productivity of IVD instruments.

Adding fluid connectors to IVD instruments increases their reliability and productivity.

Fluid connectors are used in IVD equipment to handle reagents and bulk fluids, and they play a critical role in ensuring the accuracy and safety of test results.

Fluid connectors play an important role in enhancing the reliability and productivity of IVD equipment, here are five ways that can be used to improve the handling of fluids in IVD equipment through the use of fluid connectors:

1. Compatibility of materials and media: Connectors or other fluid handling components must be compatible with the fluids used in the test setting to prevent leaks, contamination, or corrosion. A mismatch can lead to costly maintenance. For example, high-end applications using stronger acids and solvents may require components made from engineered polymers like PEEK or PVDF to remain compatible.

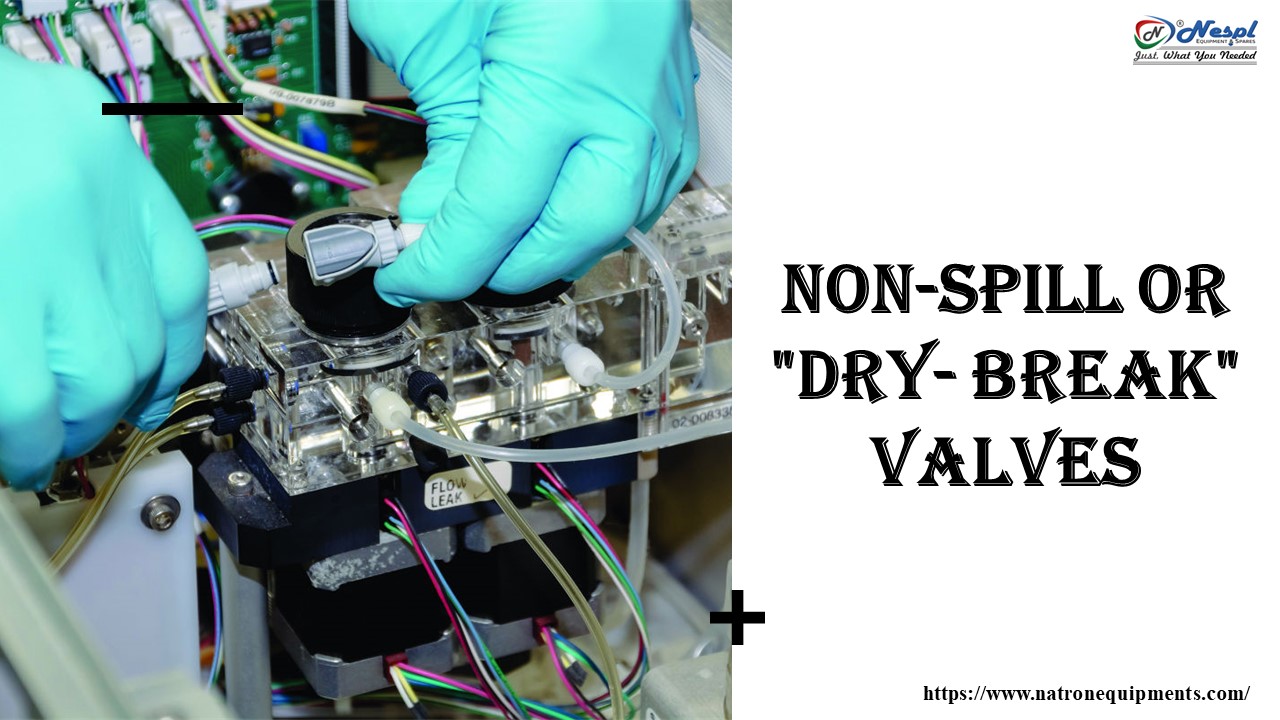

2. Non-spill or “dry break” valves: Connectors with integral valves eliminate the need for clamps and secondary shutoff valves, improving overall instrument perception. Air cannot enter the system through valved connectors since pills upon disconnection. Flow rates and pressure drops vary with valve styles. For example, non-spill quick disconnects in key assemblies of high-volume chemistry analyzers make servicing easier. The use of non-spill connections allows lab technicians to replace pumps and other critical components without worrying about damaging delicate electrical assemblies.

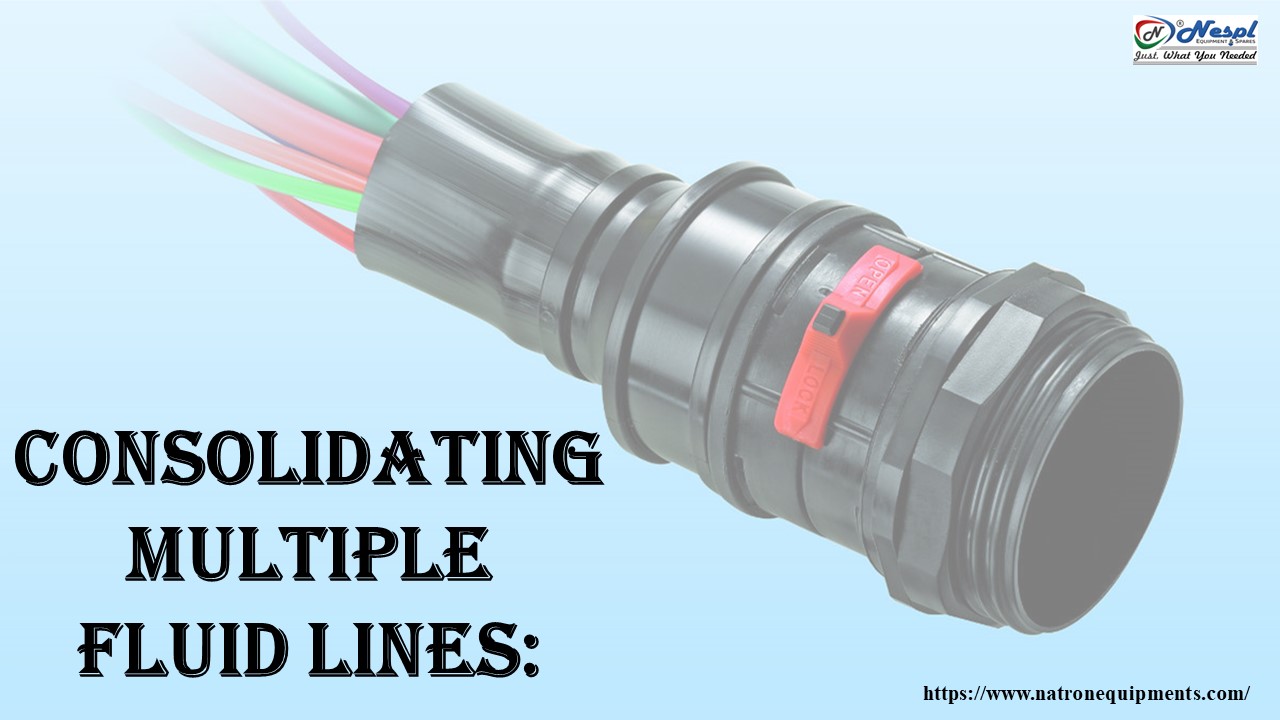

3. Consolidating multiple fluid lines: When multiple fluid lines are consolidated into one connection, serviceability and misconnections can be greatly improved. For instance, flow cytometry is routinely used for detecting blood cancers and requires secure connections to ensure proper reagent delivery and waste removal. When a hybrid-style coupling is attached to an umbilical line, electronics, sheath, and waste fluid can be carried simultaneously.

4. Disposable packaging: Disposable packaging such as bottles, bag-in-box, and puncture seals can be used for reagents, bulk fluid containers, and waste containers. A bag-in-box packaging system allows for nearly 100% fluid utilization by eliminating inaccessible fluid below a dip tube. As an alternative, reusable caps or port fittings can be substituted for cost-effective puncture seal connectors for streamlined interchangeability.

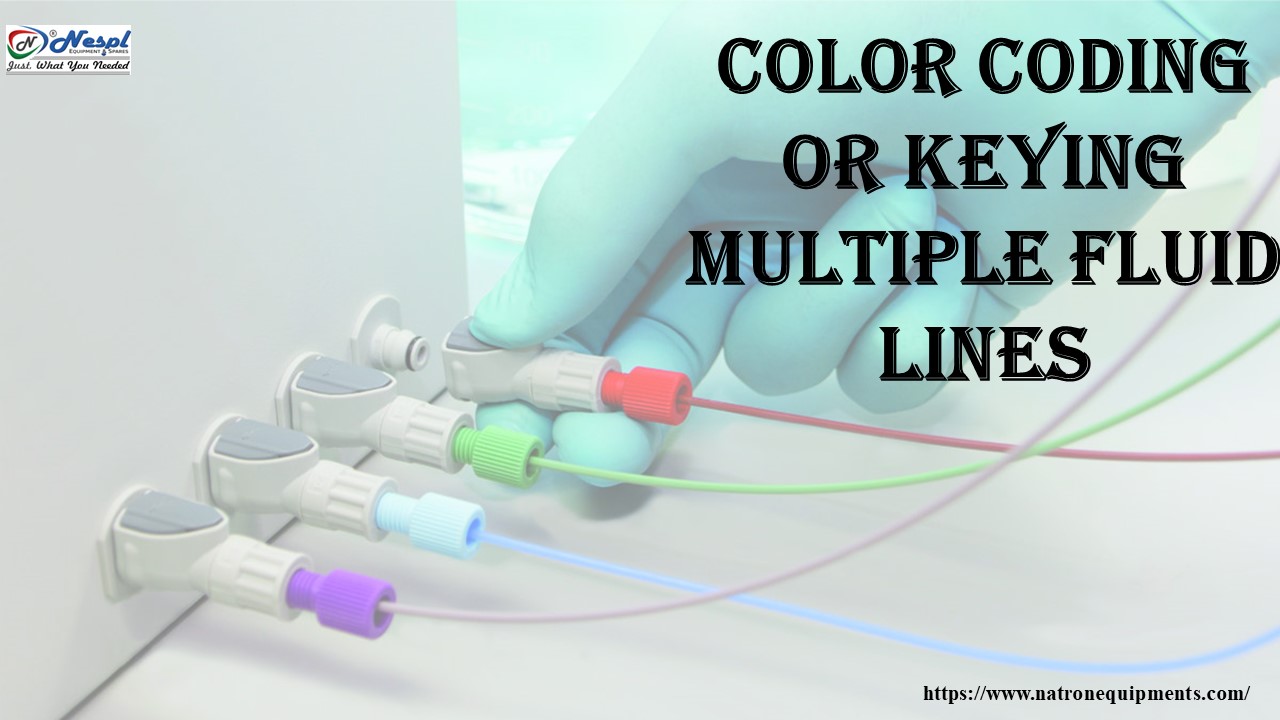

5. Color coding or keying multiple fluid lines: To prevent misconnections, color-coding or keying connectors should be used on large, automated immunoassay instruments where multiple reagent supply lines, rinse lines, and waste lines are co-located.

By ensuring compatibility of materials and media, using non-spill or “dry break” valves, consolidating multiple fluid lines, using disposable packaging, and color coding or keying multiple fluid lines, IVD equipment can be made more efficient, reliable, and safe for use.

CPC makes one of the best fluid connectors in the world. NESPL represents CPC Products in India as the privileged merchant. As an all-in-one solution provider for buying CPC products, NESPL is your one-stop shop. If you’re looking for CPC fittings for the Medical Industry, you’re in the right place. NESPL provides the best assistance to you regarding your complex requirements. So, if you want to buy any CPC fittings or couplings, Contact NESPL directly to get an expedited response.

Must Visit: https://www.natronequipments.com/medical-core-thermal-industry